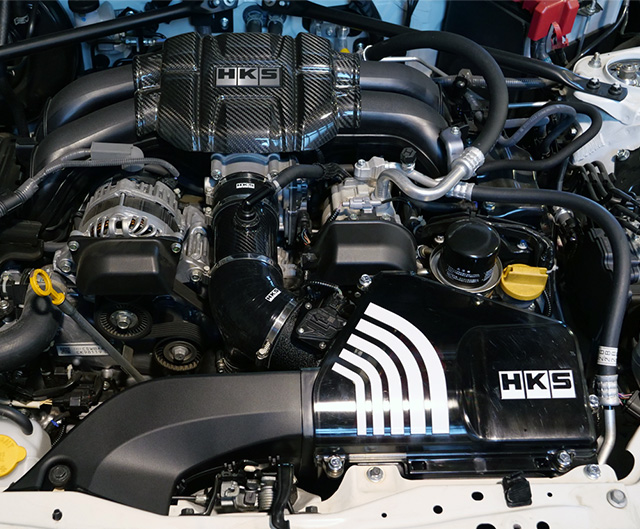

HKS COLD AIR INTAKE FULL KIT FOR TOYOTA GR86 ZN8 SUBARU BRZ ZD8 FA24

70026-AT012

$1,991.84

Tax included

200 Items

Why Buy From Us?

- ✔ Australian Company

- ✔ 100% Fitment Guarantee

- ✔ Genuine Quality Brands

Code No. 70026-AT012

Intake system consisting of a cold air intake, carbon suction pipe, and intake duct.

Cold Air Intake

Carbon Suction Pipe

Air Intake Duct

■Cold Air Intake Box

- To improved intake efficiency, the air cleaner features the traditional high performance “Super Power Flow (D150-80, wet type, 2 layers)”

- By containing the Super Power Flow inside in the box, this helps reduce the effect of hot air in the engine compartment and stabilizes intake air temperature at a lower level.

- The air flow meter is in the same position as stock to comply with the factory control. An additional second intake duct has been added to reduce airflow resistance during intake.

- The upper case of the box is clear smoke colored that complements the engine compartment, while nonchalantly showing off the Super Power Flow.

Precaution

- Circular marks are found on the inside of the air cleaner cover. In addition, the air cleaner cover may become dimmed. These are due to manufacturing reasons and are not due to product defects.

- Do not use organic solvents when cleaning. The solvent may melt the resin.

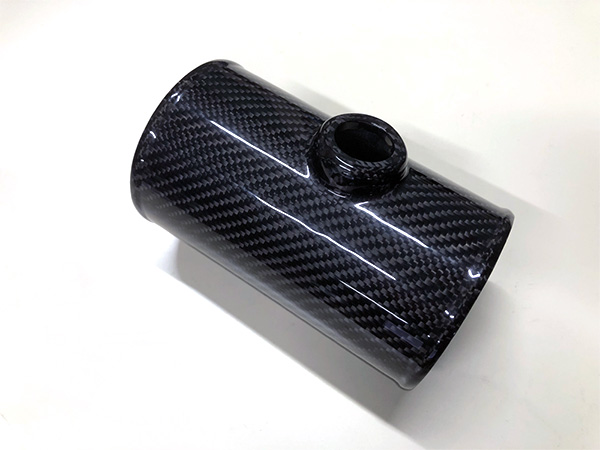

●Carbon Suction Pipe

- Using the hot press method, the surface is made of 3K* twill weave carbon prepreg* while using UD* prepreg on the inside.

- The curing process is performance by using a silicon bag on the inside of the pipe at high pressure and high temperature. As a result, high strength is achieved in addition to a smooth inner surface. Air flows smoothly while retaining sufficient strength.

- High temperature resistant silicone hose are used for connection to the intake box. The smooth internal surface reduces intake resistance, while the internal core wire suppress deformation and improves reliability.

* 3K: 3,000 Carbon Fibers

* Prepreg: Heat cured resin containing fibers in advance

* UD: Single-direction carbon fiber. UD achieves high strength by laminating multiple sheets in different stacking orientations.

●Air Intake Duct

- A one-piece molded construction without internal seams was adopted, to reduce intake resistance.

- Aiming to reduce resistance at maximum flow rate, the narrowest section diameter is D87.5mm, while the factory diameter is D50mm.

- Due to the same layout as the factory unit, it does not absorb rainwater and can be used safely on the street.

■Cold Air Intake Box

- To improved intake efficiency, the air cleaner features the traditional high performance “Super Power Flow (D150-80, wet type, 2 layers)”

- By containing the Super Power Flow inside in the box, this helps reduce the effect of hot air in the engine compartment and stabilizes intake air temperature at a lower level.

- The air flow meter is in the same position as stock to comply with the factory control. An additional second intake duct has been added to reduce airflow resistance during intake.

- The upper case of the box is clear smoke colored that complements the engine compartment, while nonchalantly showing off the Super Power Flow.

Precaution

- Circular marks are found on the inside of the air cleaner cover. In addition, the air cleaner cover may become dimmed. These are due to manufacturing reasons and are not due to product defects.

- Do not use organic solvents when cleaning. The solvent may melt the resin.

●Carbon Suction Pipe

- Using the hot press method, the surface is made of 3K* twill weave carbon prepreg* while using UD* prepreg on the inside.

- The curing process is performance by using a silicon bag on the inside of the pipe at high pressure and high temperature. As a result, high strength is achieved in addition to a smooth inner surface. Air flows smoothly while retaining sufficient strength.

- High temperature resistant silicone hose are used for connection to the intake box. The smooth internal surface reduces intake resistance, while the internal core wire suppress deformation and improves reliability.

* 3K: 3,000 Carbon Fibers

* Prepreg: Heat cured resin containing fibers in advance

* UD: Single-direction carbon fiber. UD achieves high strength by laminating multiple sheets in different stacking orientations.

●Air Intake Duct

- A one-piece molded construction without internal seams was adopted, to reduce intake resistance.

- Aiming to reduce resistance at maximum flow rate, the narrowest section diameter is D87.5mm, while the factory diameter is D50mm.

- Due to the same layout as the factory unit, it does not absorb rainwater and can be used safely on the street.

![APEXi - Power Intake Panel Filter - 2008-2014 Subaru Impreza WRX / STI [GR] : KYP Performance House](https://www.kyp.com.au/25191-home_default/apexi-power-intake-panel-filter-2008-2014-subaru-impreza-wrx-sti-gr-.jpg)